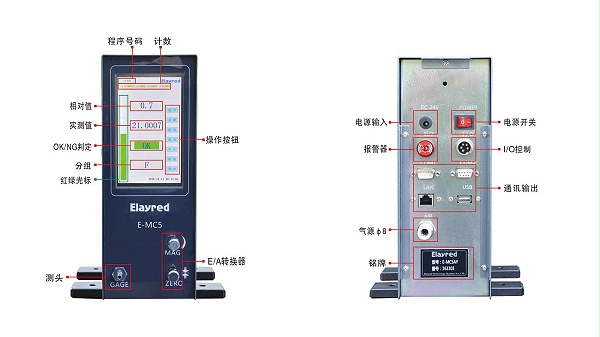

The working principle of the air momentum meter is to convert the size change of the workpiece into the change of the flow rate or pressure of the compressed air, and then it is indicated by the indicating device, so as to obtain the error of the size of the workpiece. During the measurement process, it can remove the remaining abrasive particles or coolant on the surface of the workpiece to be measured through its own compressed air, which greatly reduces the cleaning process of the part. At the same time, the pneumatic probe is not in direct contact with the measured surface, avoiding the surface of the parts being scratched, with simple structure, self-cleaning, non-contact measurement and easy operation and maintenance. Eileride focuses on precision parts size pneumatic measurement, independently developedElectronic gas meter,Full touch control, panel waterproof ratingIP55External serial communication can expand other measuring equipment,USBThe interface can be connected externallyUDisk export data,I/OIt can be controlled externally, and can be measured quickly and accurately with online detection of measuring tools, and promote quality improvement.

What is the advantage of the electronic air momentum meter over the buoy type measuring meter?

What are the detection methods for the position accuracy of shaft parts?