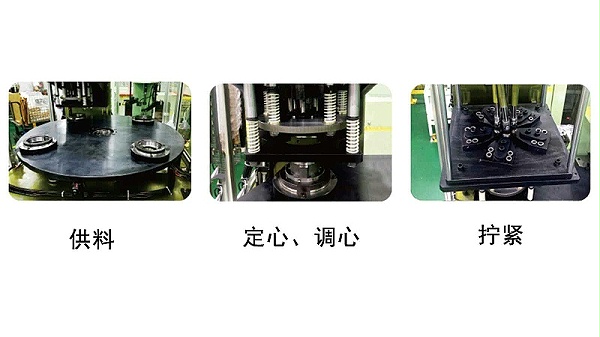

With the development of the market and the increase of production capacity, the customer's existing measurement method can no longer meet the current daily production measurement demand. As the world's largest compressor supplier, every rotary compressor pump body has the bearing aligning measurement demand, so our old customers come to us to discuss with us. Is it possible to provide a rotary aligning and crankshaft torque four-station detection machine to solve the current problem? Therefore, we have designed a set of rotary aligning and crankshaft torque four-station detection machine program to provide them.

Increased capacity, useBillion leridetheRotary aligning, crankshaft torque four-station testing machineEquipment, exceeded expectations, worked very well, all day24The stable and trouble-free production of the hourly assembly line body ensures the production capacity and pass rate required by customers. The multi-station automatic rotation, the aligning of the bearing part of the pump body, and the torque detection of the crankshaft part greatly improve the production efficiency of customers. The cooperation between us is getting closer and closer, and I believe that in the future, our cooperation will be a higher level.

Deepen the partnership and provide measuring equipment for Mitsubishi in Thailand

Qingdao Ruizhi piston (ring, roller) automatic pneumatic measuring machine case