In the manufacturing industry, the manufacturing and measurement of precision parts is a key link to ensure product quality. With its unique advantages, pneumatic measuring equipment has become an ideal choice for precision parts measurement.

First of all, the pneumatic measuring equipment has the characteristics of high precision. Using pneumatic sensors and related technologies, these devices are able to achieve measurement accuracy at the micro or even nanometer level, meeting the strict tolerances of precision components. In addition, pneumatic measurement equipment usually adopts non-contact measurement methods, effectively avoiding parts wear or measurement errors caused by contact.

Secondly, the pneumatic measuring equipment has the ability to measure quickly. Compared with traditional mechanical measuring equipment, pneumatic measuring equipment has obvious advantages in measuring speed. Its high response speed and efficient signal processing capability enable the pneumatic measurement equipment to quickly and accurately complete the measurement work of a large number of parts, thereby improving production efficiency.

In addition, the pneumatic measuring equipment also has good stability and reliability. In the production environment, the pneumatic measurement equipment can adapt to various temperature, humidity and other changes to maintain stable measurement performance. At the same time, its structure is compact and easy to maintain, which greatly reduces the failure rate and use cost of the equipment.

It is worth mentioning that pneumatic measurement equipment usually has a high degree of automation. By integrating automatic control and data processing technology, pneumatic measurement equipment can realize automatic measurement, automatic data acquisition and processing, greatly reducing manual participation and human error.

In summary, pneumatic measuring equipment with high precision, rapid measurement, stability and reliability and high degree of automation advantages, become the ideal choice for precision parts measurement. With the continuous development and technological progress of the manufacturing industry, pneumatic measuring equipment will be widely used in more fields, providing strong support for the improvement of product quality and production efficiency.

If you areDigital display gas momentum meter Interested or want to know more details, please click on our online customer service for consultation, or directly call the national unified service hotline 400-682-7787 . We look forward to hearing from you!

Precautions for using the gas meter

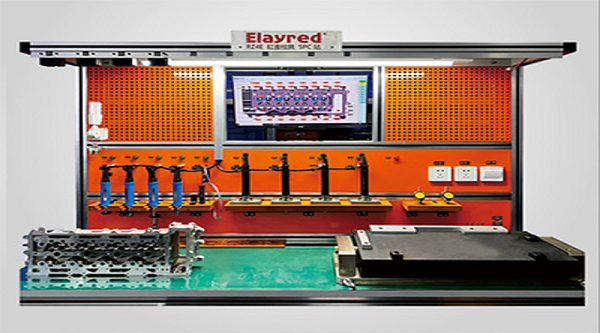

SPC Measurement Workstation: The core power of accurate measurement