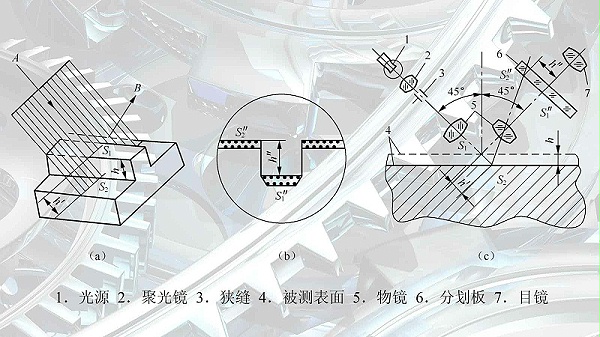

Two, light cutting method.Optical cutting method is a method of measuring surface roughness by using the principle of optical cutting, that is, the principle of light reflection. The commonly used instrument is the optical cutting microscope (double-tube microscope), which is suitable for measuring the plane or cylindrical surface of the part machined by turning, milling, planing or other similar machining methods. Optical cutting method is mainly used to measure roughness parametersRz, whose measurement range is0.8~50μm.

Working principle of light cutting microscope

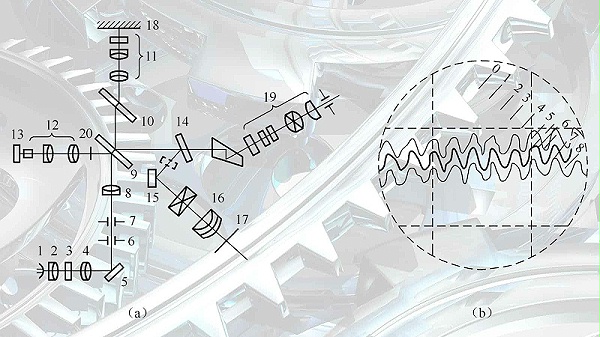

Three, light wave interference method.Light wave interferometry is a method to measure surface roughness by using the interference principle of light waves. The commonly used instrument is interference microscope, which is suitable for measuring roughness parametersRz, the measuring range is0.05~0.8μm.

Optical wave interferometry measurement principle diagram

Four, needle tracing.The working principle of the needle tracing method is to use the diamond stylus to move slowly at the same speed on the measured surface, and the micro unevenness of the measured surface will make the stylus move up and down in the vertical direction. The micro movement is converted into an electrical signal by the sensor, and is amplified and processed to obtain the relevant values of the measured parameters.The original gauge must do this work before use...

How to choose the right gauge type?