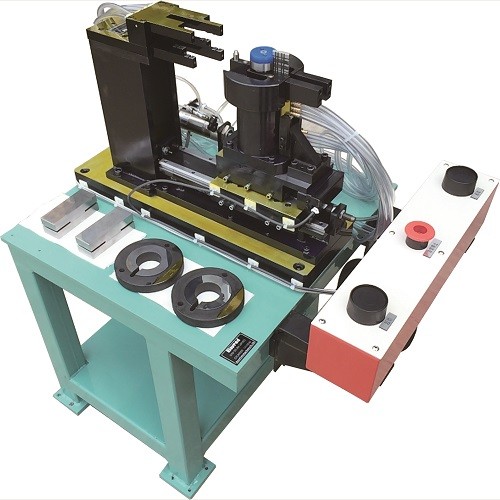

As an efficient and accurate measuring tool, pneumatic measuring bench plays an important role in many industrial fields. It is widely used, which not only improves production efficiency, but also ensures product quality.

In the field of mechanical manufacturing, pneumatic measuring table is an indispensable measuring equipment. It can quickly and accurately measure the size, shape and position accuracy of mechanical parts, helping producers to achieve precision machining. At the same time, the pneumatic tester can also detect the surface roughness and defects of the parts to ensure that the product meets the design requirements.

In the automobile manufacturing industry, the pneumatic measuring platform also plays an important role. The automobile manufacturing process involves the assembly of a large number of parts, and the accuracy and matching degree of parts are very high. The pneumatic measuring bench can accurately measure automotive parts to ensure assembly accuracy and improve the overall performance and safety of the vehicle.

In addition, in the aerospace field, the pneumatic measuring platform is also widely used. Aerospace products have high requirements for accuracy and reliability, and the pneumatic measuring platform can achieve accurate measurement of complex parts such as aircraft and rockets, providing strong support for the development and manufacturing of aerospace spacecraft.

In addition to the above areas, pneumatic measuring platforms are also widely used in the electronics industry, medical device manufacturing and other fields. In the electronics industry, pneumatic gauges can be used to measure the size and position accuracy of electronic components to ensure the manufacturing quality of circuit boards. In the field of medical device manufacturing, pneumatic measuring platforms are used to measure the accuracy and safety of medical devices to ensure the safety of patients.

In summary, the application scenarios of pneumatic measuring platforms are very wide, involving many industrial fields. Its efficient and accurate measurement capabilities provide a strong guarantee for industrial production and promote the sustainable development of related industries.

If you areDigital display gas momentum meter Interested or want to know more details, please click on our online customer service for consultation, or directly call the national unified service hotline400-682-7787 . We look forward to hearing from you!

Those conditions must be met for precision parts to be measured with pneumatic gauges

Pneumatic measurement has absolute advantages in the field of high precision and high precision manufacturing