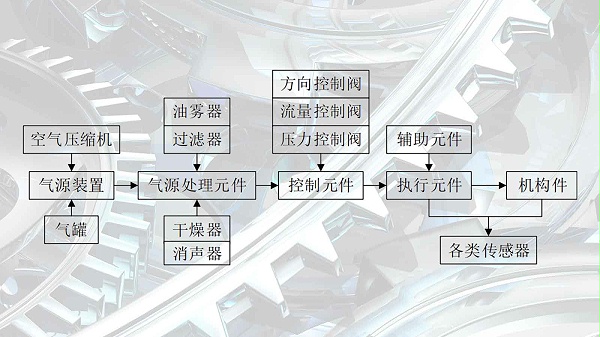

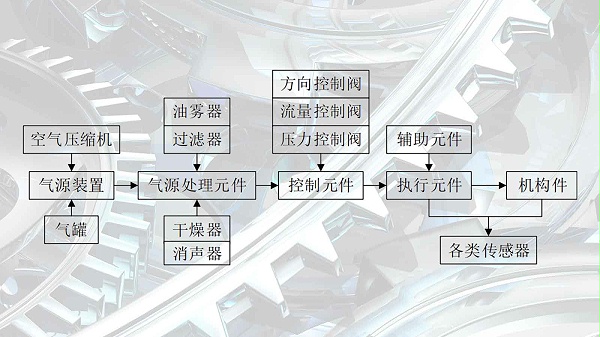

Pneumatic transmission is a system that transmits power and control signals with compressed air as the working medium. Typical pneumatic transmission system byAir source device, transmission medium, control element, executive element and auxiliary elementEqual composition.

Air source device:Including air compressor, gas storage tank and output pipeline. It provides clean, dry compressed air with stable pressure and sufficient flow for pneumatic equipment, and its role is to convert the mechanical energy output of the prime mover into the pressure energy of the air;

Transmission medium:Generally air medium;

Control elements:It is an important component for controlling the pressure, flow rate, flow direction and sending signals of compressed air, which is divided into pressure control valve, flow control valve, direction control valve and logic components, used to form various pneumatic circuits, and make the pneumatic actuator run normally according to the designed program;

Executing elements:It is a conversion device that converts the energy of the gas into mechanical energy, which is divided into cylinders and air motors. Among them, the cylinder is used to achieve linear reciprocating movement or swing, output force and linear or swing displacement, to achieve continuous rotating movement, output torque and angular displacement;

Auxiliary components:These include filters for purifying air, oil foggers to improve air lubrication, mufflers to eliminate noise, and pneumatic sensors to feel and transmit various information.

Focusing on micro-precision, Eleride provides measuring equipment and technical services for home appliances (compressors), automotive, aerospace (aerospace), precision machining, semiconductor manufacturing and other industries. If you are

Billion lerideInterested or want to know more details, please click on our online customer service for consultation, or directly call the national unified service hotline

400-682-7787. We look forward to your call!