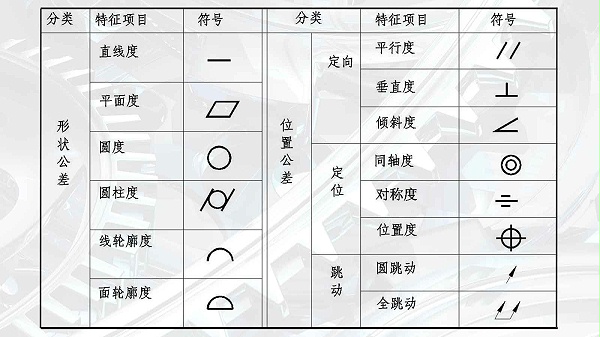

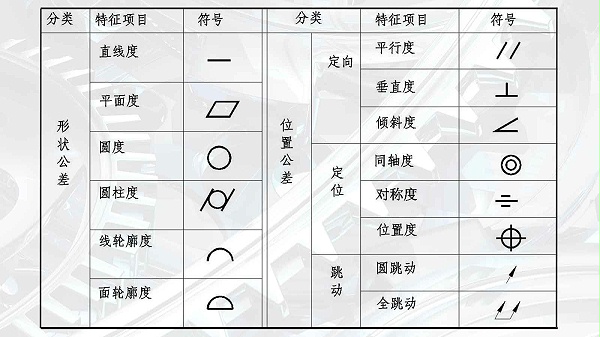

Affected by the positioning error on the machine tool in the process of workpiece processing, the relative movement of the tool and the workpiece is incorrect, the workpiece deformation caused by the clamping force and cutting force, the release of the internal stress of the workpiece, and other factors, the actual shape or mutual position of the point, line and surface of the geometric feature of the part will be different from the shape and mutual position specified by the ideal geometry, and the difference in shape is the shape tolerance. The difference between the positions is the position tolerance, and these differences are collectively referred to asForm and position tolerance. As for form and position tolerances, justBillion lerideLet's introduce the following terms.

1.Elements:Refers to the points, lines and surfaces that constitute the geometric features of a part.

2.Ideal elements:Elements of geometric significance.

3.Actual elements:Elements that are actually present on the part are usually replaced by measured elements.

4.Benchmark elements:The element used to determine the direction or (and) position of the measured element, referred to as the datum, is the basis for confirming the geometric relationship between the elements, including the datum point, datum line and datum plane.

5.Factors to be measured:Elements of shape or (and) position tolerances are given.

6.Central element:A point, line, or surface having a symmetric relationship with an element.

7.Tolerance zone:The region that limits the variation of the actual shape element or the actual position element is a region with a given maximum error, determined by size, shape, direction, and position.

Located in the Suzhou Industrial Park of China-Singapore cooperation, Eleride focuses on micro-precision, providing measuring equipment and technical services for home appliances (compressors), automotive, aerospace (aerospace), precision machining, semiconductor manufacturing and other industries. If you are

Billion lerideInterested or want to know more details, please click on our online customer service for consultation, or directly call the national unified service hotline

400-682-7787. We look forward to your call!