The use of a pneumatic gauge to measure workpiece dimensions has many advantages:

1.Multiple measurement contents

Measurement content can include a lot, such as length, shape and position errors, especially for some of the mechanical measuring tools and measuring instruments difficult to solve the measurement, such as: deep hole diameter, small hole diameter, narrow slot width, pneumatic measurement is also relatively easy to achieve.

2.Small error

The magnification of the measuring instrument is high and the human error is small, which will not affect the measuring accuracy. There is no mechanical friction during operation, so there is no return error.

3.The measurement results have little effect

The measuring head is not directly in contact with the measured surface, reducing the impact of the measuring force on the measurement result, while avoiding scratching the surface of the measured part, especially for the measurement of thin-walled parts and soft metal parts.

4.Long service life

Due to the non-contact measurement, the measuring head can reduce wear and tear, and can effectively extend the service life if the correct use and maintenance methods can be followed.

5.telemetry

A hose connection is adopted between the main body of the gas gauge and the measuring head to realize remote measurement.

6.Easy to use

The gas momentum meter is simple in structure, reliable in operation, easy to adjust, use and maintain, and even an inexperienced operator can use the gas momentum meter for accurate measurement. The operation process is as simple as placing a ruler on the workpiece and reading it, fast and accurate.

7.Economical and practical

As long as the basic measurement system is purchased, with the relevant inexpensive auxiliary measurement tools, a variety of measurement applications can be realized. The pneumatic gauge can effectively measure a variety of common dimensions, especially suitable for measuring form and position relationships and fitting tolerances.

8.Easy to clean

Most of the compressed air used in the measurement of the gas meter can remove the residual abrasive particles or coolant on the workpiece under test, so the use of the gas meter can reduce the cleaning process of the part to a certain extent. Since the gas meter itself has no moving parts, it is basically immune to dirt.

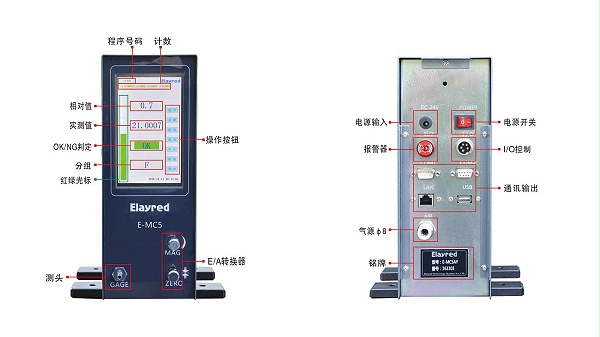

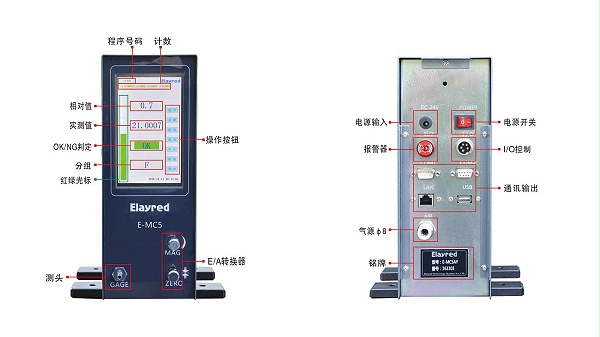

As a precision parts size pneumatic measurement equipment manufacturers, focusing on micro-precision, R & D and production of digital display pneumatic momentum meter, a variety of models, quality assurance, manufacturers direct sales, price concessions.

If you are

Digital display gas momentum meter Interested or want to know more details, please click on our online customer service for consultation, or directly call the national unified service hotline

400-682-7787. We look forward to hearing from you!