The accuracy of precision parts almost determines the quality of the product, the more precise the hardware parts, the higher the precision requirements. So, why will the precision of precision parts become worse?Billion leride summary mainly has the following three points:

First, the machining accuracy of the parts themselves is poor, in general, if the dynamic error between the shafts is not well adjusted during the installation process, or changes due to the wear of the shaft transmission chain, it will affect the accuracy of the parts. In general, the accuracy check caused by this error can be solved by re-adjusting the compensation. If the error is too large or even if there is an alarm, you need to check the servo motor to see if its speed is too high.

Second, the overshoot of the machine tool during operation will also affect the processing accuracy, which may be because the acceleration and deceleration time is too short, and the replacement time is appropriately extended. Of course, it is also likely that the connection between the lead screw and the servo motor is loose.

Third, because the roundness of the two-axis linkage is out of whack, the machine is not properly adjusted to form a circular axial deformation, and the screw clearance compensation of the shaft is not correct or the shaft positioning is offset, which may affect the accuracy of the precision parts.

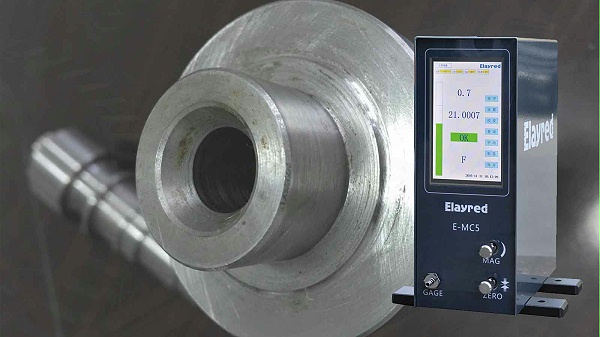

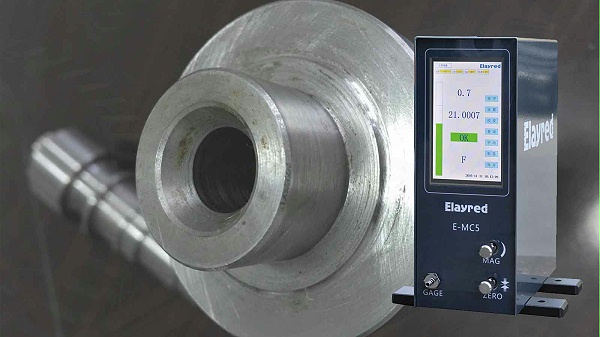

Billion leride Focusing on micro-precision, we provide measuring equipment and technical services for home appliances (compressors), automotive, aerospace (aerospace), precision machining, semiconductor manufacturing and other industries. If you are interested or want to know more detailed information, please click on our online customer service for consultation, or call the national unified service hotline directly

400-682-7787. We look forward to your call!